Invented by the Italians, Norway Stitch is an older hand-made shoe sewing method than Goodyear (Goodyear Welt). This more than 200-year-old craft is complicated and without To replace it with a machine, so that today it is only used in the top custom shoes.

There are only a handful of shoemakers with "handmade Norwegian stitch".

Hector Maden challenges the difficult Norwegian seam, one is to pay tribute to its palace-level craft status,

The second is to put more effort into the word "handwork" and continuously improve it.

Norwegian seams that can only be operated purely by hand retain the purity of handmade shoes;

Intricate Norwegian sewing shoe craftsmanship, extremely waterproof:

The Norwegian seam, which was first used in mountaineering shoes, has superior toughness, strength and comfort;

Not only is it unique and beautiful in appearance, but it can also adapt to harsh and complex environments.

Norwegian Stitch was first used in hiking shoes

Mountaineering is a sport that constantly challenges the physical and psychological limits of human beings. When it began to rise as a sport in Europe in the late 17th century, people continued to follow suit without hesitation. Many inventions have been born from this. Police such as Climbing Knot, Trekking Pole and the like, and Norwegian Stitch for hiking Boots.

The extremely harsh and complicated environment requires boots to have excellent waterproof and snowproof. The Norwegian Stitch process ensures that the upper leather, edges, sole or midsole are held together for added toughness, strength, and comfort.

Norwegian Stitch is even more protective than Storm Wet. Therefore, it is widely used in the production of outdoor shoes such as Outdoor hiking Boots. The personal equipment of the European army has always been developed with outdoor mountaineering products. During the Battle of the British Armagh Islands, the soldiers of the British Marine Corps marched under the harsh terrain and weather conditions of the Maldives Islands. They liked to wear this kind of European outdoor mountaineering products. shoe.

With the development of industrialization, Norwegian Stitch, which cannot be mass-produced, is rarely seen in mountaineering equipment. However, such as Zamberlan ALICO and GRONELL still have limited editions of mountaineering shoes combined with Norwegian Stitch. Of course, this is all from the Italian luxury brand.

Norwegian Stitch that can only be "Hand Made"

Norwegian Stitch, as a traditional artisan technique, has been passed down for centuries and is regarded as the top sewing technique in handmade shoes. Norwegian sewing shoes can still be seen in brands such as Berluti, Paraboot, Loake, and John Lobb, and others such as Ferragamo and Louis Vuitton occasionally dabble.

Most of the classic crafts of shoemaking were basically replaced by machines later, and the machine sewing was more beautiful and the efficiency was greatly improved.

Norwegian Stitch, however, has been sewn by hand for more than 200 years. It has been handed down from master to apprentice. So far, no machine can replace handwork.

Norwegian Stitch's "slow and careful work" makes it rare and impossible to mass produce. Although the reputation is great, there are very few people who have seen it, and there is very little that can be done. Finding the Norwegian seam has naturally become the most unspeakable pain for "players".

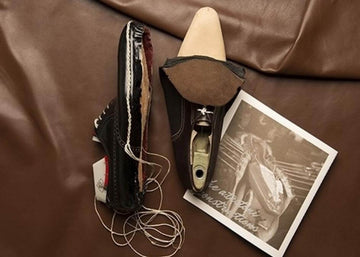

Norwegian Stitch is also particular about it. Just the line from the midsole to the upper gives rise to four stitching methods. One-word style, triangular style, two-line style, chain style. Among them, the most complicated chain type, in addition to being more beautiful in appearance, the interlocking stitching method also makes the shoe body stronger and stronger.

A pair of genuine Norwegian Stitch handmade shoes

Norwegian Stitch is only used in custom or top-of-the-line shoes. Not only because the process is complex and cumbersome, time-consuming and labor-intensive, but also because few people can do it.

A pair of pure Norwegian hand-stitched shoes requires many processes, the most special hand-stitching stage is an inheritance in the industry. Hector Maden dared to "explain to the world" because of

Practicality is far more difficult than what you see, superficial effects are useless!

British GOATS wax thread, from the midsole to the leather surface, the needles are interlocked, shuttle forward, circle around the shoe, the most test of skill!

It takes at least 7 hours to sew Norwegian Stitch by hand! There is no substitute for machines!

First, different from Goodyear, the Norwegian stitched upper is turned upside down, hand-stitched with the first layer of outsole, and the inside of the shoe is completely isolated from the outside world;

Second, cut off the excess part of the vamp by hand. The knife rises and falls, and there can be no deviation;

The third and second leather bottoms are sewn together with the outer outsole. In this way, the midsole, upper, and the two outsoles "collude" with each other, doubling the firmness;

The cumbersome and beautiful chain line has a distinctive and unique style. The Norwegian stitched shoes with three stitches are fully presented after being polished and waxed. Pure handmade crimson thread, high-quality leather, oiled wood-colored shoes, more ancient, Norwegian Stitch is the top craftsmanship in handmade shoes, its occurrence frequency is very low, and "shoes" experts can't wait to search the world . Even if it is turned over, the price is "outstanding the crowd". Police such as louis vuitton launched a semi-Norwegian Stitch formal men's leather shoes in 2015, the price of which is close to 2,000 US dollars.